PVC Hose

What Is PVC Hose

PVC hose is a flexible, lightweight and durable type of hose made from polyvinyl chloride (PVC). It is used for a variety of applications such as gardening, plumbing, industrial use and more. PVC hose is resistant to chemicals and UV radiation, making it an ideal choice for outdoor use. It is also easy to install and requires minimal maintenance. PVC hose is available in different sizes and colors to suit your needs.

Advantages of PVC Hose

Smooth

The wall of pvc hose is very smooth, so the water delivery effect is very good.

Good Corrosion Resistance

The corrosion resistance and chemical resistance of pvc hoses are also very good. It has good acid and alkali resistance characteristics, is not affected by moisture and soil ph, and has a long service life.

Good Water Tightness

The pvc hose also has good water tightness. This kind of hose can maintain good water tightness no matter it is connected by bonding or rubber ring.

Good Stretchability And Thermal Stability

The pvc hose has good stretchability and thermal stability, and can be used in different environments with a wide range of applications.

Why Choose Us

Our Factory

Founded in 2010, located in the beautiful kite capital of the world ---- Weifang. Weifang Sansen Plastic machinery Co., Ltd. is a professional plastic machinery manufacturer especially in PVC plastic hose production line.

Our Product

The company mainly produces plastic machinery, leading products are PVC fiber reinforced hose production line, PVC steel wire reinforced hose production line, Plastic bag making machine, PP-R unit, PET (PP) packing belt production line, PVC PE PP granulation unit, PVC foam hose production line and other types of plastic machinery.

Strong R&d Team

The company has strong R&D team and advanced management system, with good equipment, excellent products, perfect after-sales service to create good economic and social benefits for its customers.

Our Service

We try and respond to all concerns within 24 hours and our teams are always at your disposal in case of any emergencies.

High-pressure Spray Hose

This type of pvc hose is widely utilized in gardening and agriculture. It is suitable for transferring liquids at high pressure and can handle temperatures of up to 60°c. High-pressure spray hoses are also ideal for cleaning jobs, including washing cars and other equipment.

Layflat Hose

This pvc hose is used in water distribution, including firefighting and irrigation. It is also used in construction sites for dewatering applications. Layflat hoses can operate at high pressures and temperatures of up to 50°c, making them ideal for use in various industries.

Steel Wire Reinforces Hose

This pvc hose has a steel wire embedded within the walls of the hose, giving it extra strength. This type of hose is common in environments with high mechanical stress and is ideal for industrial applications such as suction and discharge of chemicals and powders.

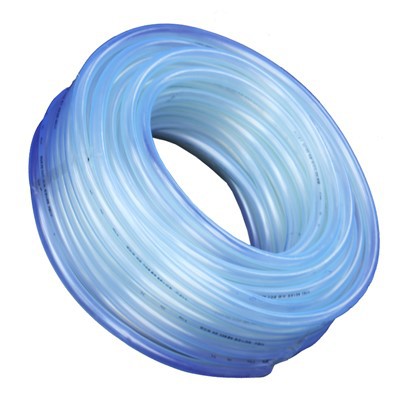

Transparent Hose

The clear pvc construction allows for the full visual inspection of liquid flow, making it ideal for use in the food and beverage industry. Transparent hoses are made of food-grade pvc material that is non-toxic and odorless, ensuring that food is not contaminated during transfer.

Gas Hose

This pvc hose is used in a range of applications where gas transfer is needed, including welding and cutting. The gas hose is reinforced with a synthetic textile to ensure that it can operate safely under high-pressure situations.

What Factors Should You Consider When Selecting a PVC Hose

Application

You need to determine the specific application of the hose and the type of fluid or gas that will be transported through it. This will help you choose the right type of PVC hose that can bear the pressure, temp and chemical of the fluid.

Temp Range

PVC hoses have different temp ratings. So it is important to choose a hose that can operate within the required temp range of your usage.

Pressure Range

PVC hoses have different pressure ratings. Thus you need to choose a hose that can handle the pressure of your app.

Size And Length

You need to select a hose with the right size and length that can fit your system. Then it can provide the necessary flow rate for your application.

Environmental Factors

You should consider the environmental factors such as sunlight exposure, abrasion, and chemical exposure that the hose will be exposed to and select a hose that is suitable for those conditions.

Compliance

If your work is subject to regulations or standards such as FDA, NSF, or UL, you need to ensure that the hose meets them.

Durability

Sometimes the hose serves in heavy duty. So you have to choose a hose that is durable enough to fit your work.

Cost

The prices of PVC hoses are different, and it is important to select a hose that fits your budget while still work well for your usage.

Selecting the Perfect PVC Hose Sizes for Your Needs

Understanding PVC hose sizes a comprehensive guide Polyvinyl Chloride (PVC) hoses have become an indispensable part of various industries due to their durability, flexibility, and cost-effectiveness. These versatile hoses are used in everything from gardening to heavy industrial applications. However, understanding the right PVC hose size for your specific needs is crucial to ensure optimal performance and efficiency. In this article, we will delve into the world of PVC hose sizes, discussing the factors that influence selection and how to measure them accurately. PVC hose sizes are typically expressed in two measurements Inside Diameter (ID) and Outside Diameter (OD). The ID determines the flow capacity of the hose, while the OD affects its strength and flexibility. Generally, PVC hoses come in sizes ranging from 1/4 inch to 4 inches or more, with pressure ratings varying accordingly. The first consideration when selecting a PVC hose is the intended application. For instance, a garden hose would typically require a smaller ID compared to a suction or discharge hose for industrial purposes. The flow rate required and the pressure at which the fluid will be transported are critical factors. Always choose a hose with an ID large enough to accommodate the expected flow without causing unnecessary resistance. Pressure rating is another essential factor. PVC hoses are rated based on their maximum working pressure, which is usually measured in pounds per square inch (PSI) PVC hoses are rated based on their maximum working pressure, which is usually measured in pounds per square inch (PSI)

PVC hoses are rated based on their maximum working pressure, which is usually measured in pounds per square inch (PSI) PVC hoses are rated based on their maximum working pressure, which is usually measured in pounds per square inch (PSI).

It's crucial not to exceed this rating, as it could lead to hose failure and potential safety hazards. Ensure you select a hose with a pressure rating that exceeds the anticipated operating pressure. Length also plays a role, as longer hoses may experience more pressure drop. While PVC hoses can be quite flexible, excessively long runs may require additional support to prevent kinking or damage. When measuring PVC hose sizes, accuracy is key. Use a tape measure or calipers to determine both the ID and OD. Remember, the ID is the inner space where the fluid flows, while the OD is the overall circumference of the hose. It's also important to check the manufacturer's specifications, as nominal sizes may not always match the actual measurements due to manufacturing tolerances. Understanding PVC hose sizes is a vital aspect of selecting the right hose for any application. By considering factors such as flow rate, pressure rating, length, and application requirements, you can make an informed decision that ensures both efficiency and safety. Always prioritize quality and adhere to industry standards to maximize the lifespan and performance of your PVC hoses.

Proper Maintenance and Care Are Essential to Extend the Lifespan of PVC Hose

Inspect The Hose Regularly

Regularly inspect the PVC hose for signs of damage such as crack, leak or wear. Then replace the hose if you notice any damage.

Clean The Hose

Clean the hose regularly with soap and water to remove any dirt. Because it can cause blockage or damage to the hose.

Store The Hose Properly

Store the hose properly when not in use. While it should be a dry and cool place. Besides, it should be away from direct sunlight and heat sources.

Avoid Sharp Bends

Away from sharp bends or kinks that can weaken the hose and cause it to crack or rupture.

Avoid Exposure To Chemicals

PVC hoses are not suitable for use with all chemicals. Avoid exposing the hose to chemicals that can cause damage to the hose.

Use The Right Fittings

Use the right fittings that fit the hose material and the fluid or gas. Because this will ensure a secure and leak-free connection. Do not exceed the pressure and temperature limits. Make sure to operate the PVC hose within the temp and pressure limits to prevent damage or failure. With these tips, you can prolong the lifespan of your PVC hose. Then you can save a lot of cost and time to repair it.

What Are the Manufacturing Processes of PVC Hose

Through research, development, and experience, the PVC hose industry has advanced and matured since the product was introduced during the Second World War. A constantly evolving product, PVC hose can be best evaluated and appreciated through an understanding- ing of its technology. Ideally, the industry's stakeholders should possess comprehensive knowledge of the advantages and limitations of the piping systems they use. Toward this end: manufacturing processes standard specifications testing requirements packaging shipping. The technology of PVC hose manufacturing processes is extensive and involved. Well before afnished PVC product is ready for testing, inspection, and delivery, its beginnings can be traced from oil or gas wells, through petrochemical plants to PVC compounding operations, and finally to automated extrusion, molding, and fabrication operations.

PVC hose is produced from a blend of materials whose major ingredient is polyviny| chloride resin. In the plastics industry, the word "resin" refers to the basic polymer used as raw material and "compound" refers to a homogeneous blend of resin and various additives. PolyinyI chloride resin is a thermoplastic polymer produced by the polymerization of viny| chloride monomer (VCM). Vinyl chloride is a colorless gas produced from chlorine and ethylene. In North America, the raw materials of vinyI chloride monomer are saltwater and natural gas. The terms thermoplasticity, polymer, monomer, and polymerization are defined as follows: Thermoplasticity refers to the property that enables a material to be repeatedly softened by an increase in temperature and hardened by a decrease in temperature. A polymer is an organic material that contains a large number of the same chemical configurations, attached to each other like links in a chain. The long chains result in high molecular weight. A monomer is the simple, small molecule from which the polymer chain is made. Polymerization is the reaction that bonds monomers into the large structure of the polymer. Polymers are not exclusively manmade; they are also found in a large variety of natural materials such as protein, cellulose, starch, and rubbers. There are many polymerization processes that convert vinyl chloride monomer into polyvinyl chloride resin (polymer). Two processes are best suited to the manufacture of the type of high-quality PVC resin needed for pipe. They are suspension polymerization and mass (sometimes termed "bulk") polymerization. These are economical processes used in the production of virtually all PVC hose- grade resins today.

After production and quality assurance, resin manufacturers ship the PVC resin (in powder form) to pipe producers. Product parameters commonly evaluated include molecular weight, particle size/dimension, volailes content, bulk density, flow time, and residual VCM. Large 200,000-b bulk railcars or 40,000-Ib bulk trucks are normally used to transport the PVC resin. Upon arrival at apipe manufacturer, the resin is pneumatically conveyed from the bulk transporters into the pipe production plant and stored in silos. Other ingredients that are compounded with the PVC resin include stabilizers, pigments, lubricants, processing aids, and functional additives. Each ingredient is used to impart specific processing characteristics or to enhance specific finished product properties. For instance, functional additives may be used to increase the PVC compound's modulus of elasticity. The proportions of these minor ingredients will vary from compound to compound. The formulations, which stipulate the percentages and actual ingredients used in a given PVC hose compound, are developed to impart specific properties dictated by the application.

Our factory

Founded in 2010, located in the beautiful kite capital of the world ---- Weifang. Weifang Sansen Plastic machinery Co., Ltd. is a professional plastic machinery manufacturer especially in PVC plastic hose production line. The company has strong R&D team and advanced management system, with good equipment, excellent products, perfect after-sales service to create good economic and social benefits for its customers. The company mainly produces plastic machinery, leading products are PVC fiber reinforced hose production line, PVC steel wire reinforced hose production line, Plastic bag making machine, PP-R unit, PET (PP) packing belt production line, PVC PE PP granulation unit, PVC foam hose production line and other types of plastic machinery. Since its establishment, the company has successfully developed many sets of production equipment for many plastic enterprises and brought good economic benefits to customers.